Constellation Nuclear

Case Studies

REQUEST A QUOTE Constellation Nuclear Improves MWh Output with PQI Testing

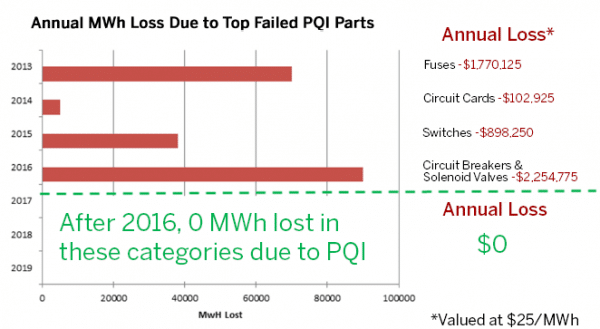

In 2016, Constellation added model specific fuses, circuit cards, switches, solenoid valves and circuit breakers to the PQI program.

Prior to these models being added to the PQI program, these model specific critical part failures cost Constellation more than $5 million in MWh force loss alone. Once these models were PQI tested before installation, critical parts failure-related SCRAMS and force loss was entirely eliminated for these models.

"“Since 2017, the Constellation fleet has had zero reactor SCRAMS or MWh lost due to failed fuses, circuit cards, switches, solenoid valves, or circuit breakers as a result of implementing PQI. What is especially valuable is that the PQI program pays for itself.” "

"“The PQI program makes my life easier as a Supply Manager. We send the part straight to Constellation PowerLabs and have reasonable assurance the part will work before we put it in inventory.” "

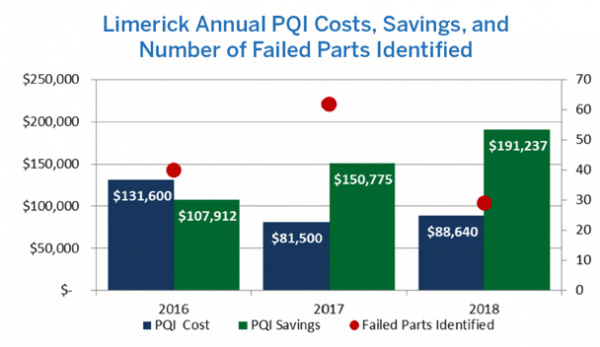

PQI Testing Identified Failed Parts Before They Entered Warranty

Examples of failed parts included cable assemblies, valve regulators, various relay types, solenoid valves, and transducers. In 2016, Limerick PQI tested a substantial portion of inventoried parts (as opposed to newly procured) which accounts for the lower warranty replacement savings since many of those failed parts were outside of the warranty window.

For many PQI community members, warranty replacement cost savings more than pays for the cost of implementing PQI year after year.