Blog

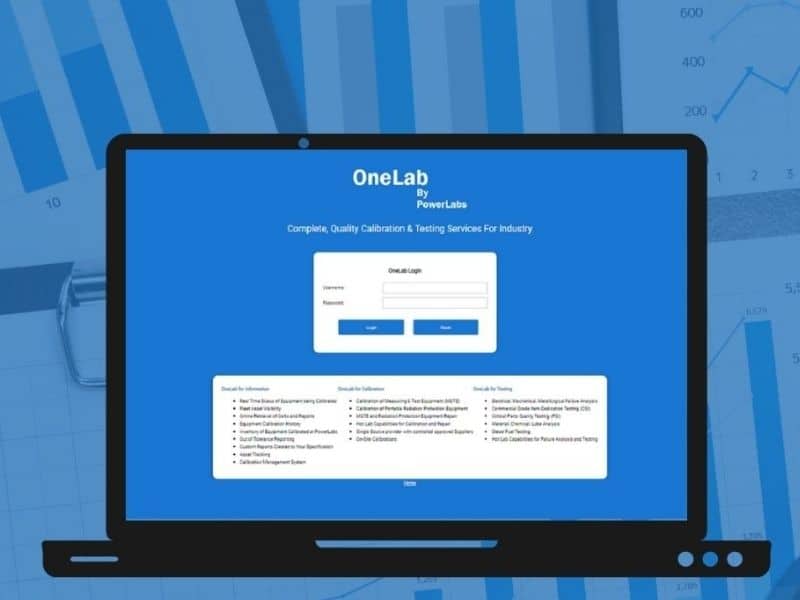

OneLab Database: A Seamless Experience for PowerLabs Customers

PowerLabs has been performing testing and calibration services for over a century. With years of accumulated data, we have invested in an online database that is not only beneficial to our engineers and technicians, but most importantly to our customers.

Read more

The History of PowerLabs’ Testing and Calibration Services

Discover the history of Constellation PowerLabs and how our labs evolved to support one of the largest energy providers in the nation.

Read more

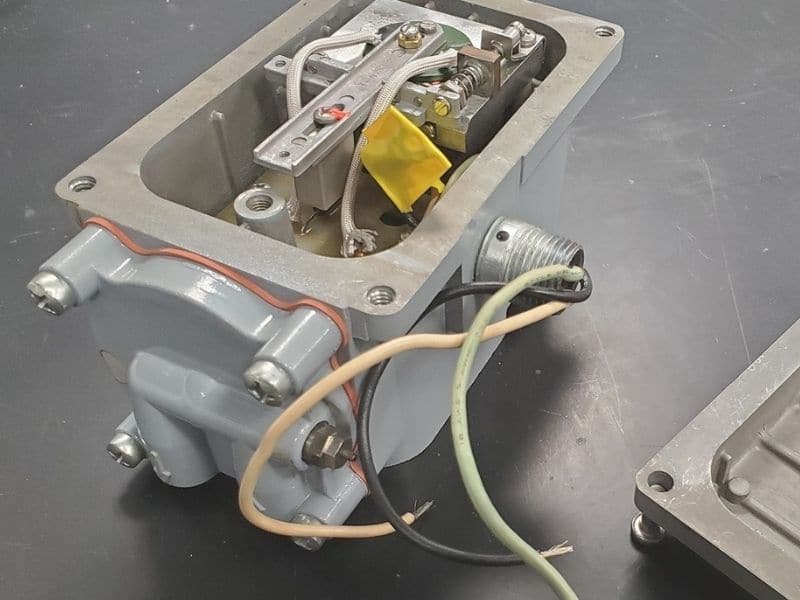

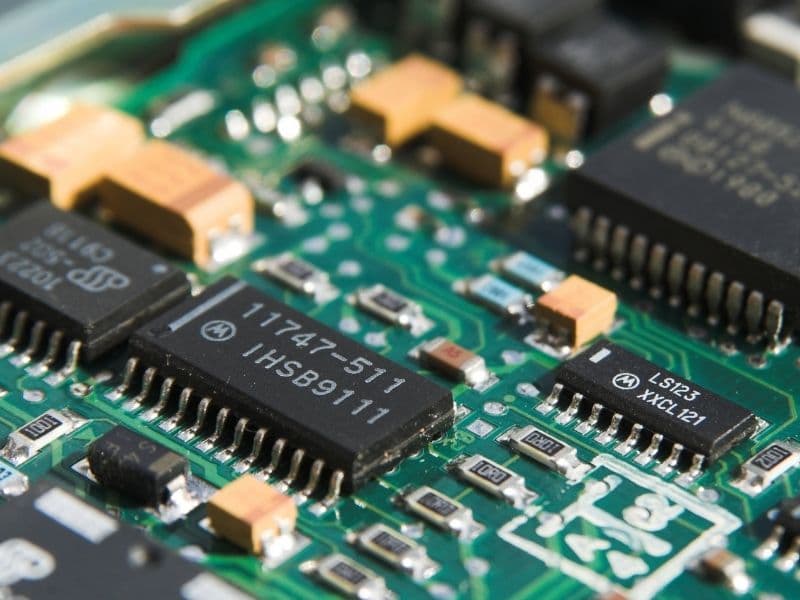

PQI Testing Brings Insight to Our Failure Analysis Services

Performing failure analysis services is essential to the continuous improvement of numerous industries including nuclear power plants, manufacturers, pharmaceuticals and more. When a part fails, it is important to take corrective action based on a solid understanding of why the component failed. Through PowerLabs’ failure analysis services, we identify the root cause of failure.

Read more

Ultrasonic Flow Calibrations and New Developing Methodologies

Ultrasonic liquid flow is a popular method used in many industries because it is a non-invasive way to measure the flow of fluid. The technology used to measure the flow rate consists of two transducers mounted on the outside of a pipe. This equipment accurately measures the fluid flow rate passing through the pipe by determining the time transient between the pulsed signal and the transducers.

Read more

Conowingo Dam Laser Scanning Case Study

A team of experts from Constellation PowerLabs went to the Conowingo Dam in Maryland to scan the inside of the hydroelectric power plant to map out this famous structure using 3-D laser scanning technology. The Conowingo dam was constructed in 1928 on the Susquehanna River and was the largest power plant that had ever been built at that time.

Read more

Getting to the Root Cause with Failure Analysis

Understanding the importance of failure analysis will help you make better informed decisions within your company. Whether it’s choosing a different manufacturer or changing the environment of the failed part, finding the true root cause of a failure can assist you in making corrective changes and preventing new failures.

Read more

How Constellation PowerLabs’ Parts Quality Initiative (PQI) Can Work for You

Throughout the years, Constellation PowerLabs has continued to support the Constellation fleet in all aspects of metrology, from calibration to failure analysis. In 2006, a new program was developed by PowerLabs when they saw the need to challenge both manufactures and suppliers.

Read more

The Voice Behind Our Metrology Services at Constellation PowerLabs – Meet One of Our Experts

Throughout the years, PowerLabs has accumulated a diverse team of experts, highly knowledgeable in not only our metrology services, but also testing, and analysis. Among the many, Cory Peters stands out as he has dedicated his career to metrology. His experience, military background, and thorough understanding of metrological science have made him an invaluable asset to PowerLabs.

Read more

Why Did This Break? Failure Analysis Can Tell You

When it comes to daily operations, product failures can occur. Items such as breakers, relays, switches, valves, order control buckets, circuit boards, and power supplies can break unexpectedly. While all parts can be replaced, the question remains, “Why did this part fail?” This is where failure analysis comes in.

Read more

Constellation PowerLabs Wins a 2018 TIP Award for its Parts Quality Initiative (PQI) Program

Every year, the Nuclear Energy Institute (NEI) recognizes the nuclear industry’s leading innovations with its coveted Top Innovative Practice (TIP) Awards. Our Constellation team’s entry has won a TIP Award this year for our Parts Quality Initiative (PQI) program.

Read more